Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Majorpack vegetable flow pack machine suitable for single/multiple variety material in 1 bag,for example:Carrots,Cucumbers;Tomatoes;Potatoes;Peppers (bell peppers, chili peppers, etc.);Zucchinis;Eggplants;Green beans; Asparagus;Broccoli;Cauliflower; Lettuce and leafy greens;Radishes;Mushrooms packaging.

Majorpack vegetable flow pack machine's Standard features:

3 independent motors (Conveyor, center sealing and end sealing);

Motion controller for quick response to various commands;

Accurate positioning;

Digital temperature control;

Food grade SUS304 contact parts;

Brush extrude air from bag;

Touch screen;

Special features:

All control in one touch screen, multi language,user-friendly and easy operation;

Empty bag prevention, no product no bag;

Product cutting prevention, machine will stop once cutter cuts the product;

Memory function, can store 99 groups of package parameters (product position, packing speed, bag length);

No limit for product length.

Majorpack Vegetable packing machine details:

|

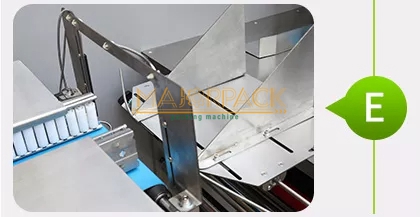

Punching device

Keep vegetable ventilated and fresh, basing on the speed and bag length to punch.

|

|

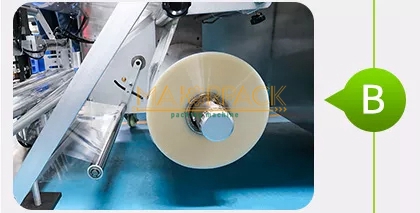

Film structure

Bigger and stronger structrue for big roller film.

|

|

|

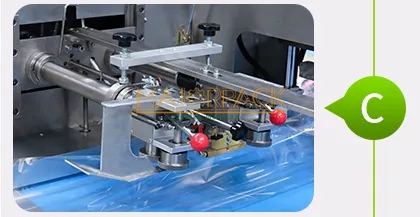

Anti-clap device

To prevent the leaves are clapped by the middle sealing device during packing. So the vegetable can be kept fresh for longer time.

|

|

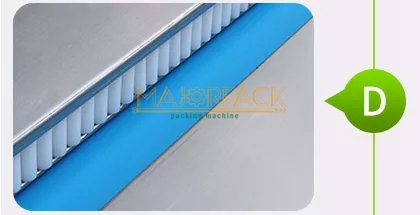

Feeding belt rollers

Flat belt feeding, suitable for bulk vegetables, rollers protect the surface of vegetables from damage during bag feeding.

V-belt can be upgraded. |

|

|

High-level through beam fibre optical sensors

Detect the different length of products automatically and no need to adjust the bag length by manual. No product, machine will stop, no empty bag, save your cost.

|

Maintenance and inspection

1.Maintenance and clean for machine every day or every shift.

(1) Clean the machine each time after packaging.

(2) Turn off the power before cleaning the machine to low the temperature of heating part.

(3) Never spray the water or steam directly on the machine when cleaning.

(4) Main components to be cleaned:

a.Remove the product chips store up in the conveyance line of the product by compressed air or in other way.

b.Brush off the film chips adhered to the sealing surface by the wire brush applied with the silicone oil.

c.Clear the dirt on the control panel, safety cover and operating surface by a piece of soft cloth.

dConductive ring of the mid sealing tool and end sealers: clean it once a week or two weeks. Clean the conductive ring by the back of the sandpaper with the master power off.

2.Maintenance and clean for machine every month.

(1) Apply the lubricating grease on the bearing of the end sealers.

(2) Apply the lubricating grease on the gear and chain (pulley) of the driving unit.

(3) Check the tightness of the chain and belt of the driving unit, and tighten the loosed one.

(4) Check the tightness of the fastening screw or nut of all parts, and tighten the loosed one.

3.Relevant inspection for machine once a half year.

(1) Check the wear intensity of the belt of the driving unit, and replace the worn-out one.

(2) Check the wear intensity of the rubber roller, and replace the one affecting the film advancing effect.

(3) Properly adjust the brake unit of the film-carrying roller.

(4) Check all wearing parts, and immediately replace the damaged one.

(5) Check the fastness of the wiring on the electrical terminal plate, and tighten the loosed one. Check the inverter, programmable controller and circuit board, and remove the dust or dirt on them by the compressed air.

4.Maintenance and clean for machine every day or every shift.

(1) Clean the machine each time after packaging.

(2) Turn off the power before cleaning the machine to low the temperature of heating part.

(3) Never spray the water or steam directly on the machine when cleaning.

(4) Main components to be cleaned:

a.Remove the product chips store up in the conveyance line of the product by compressed air or in other way.

b.Brush off the film chips adhered to the sealing surface by the wire brush applied with the silicone oil.

c.Clear the dirt on the control panel, safety cover and operating surface by a piece of soft cloth.

d.Conductive ring of the mid sealing tool and end sealers: clean it once a week or two weeks. Clean the conductive ring by the back of the sandpaper with the master power off.

5.Maintenance and clean for machine every month.

(1) Apply the lubricating grease on the bearing of the end sealers.

(2) Apply the lubricating grease on the gear and chain (pulley) of the driving unit.

(3) Check the tightness of the chain and belt of the driving unit, and tighten the loosed one.

(4) Check the tightness of the fastening screw or nut of all parts, and tighten the loosed one.

6.Relevant inspection for machine once a half year.

(1) Check the wear intensity of the belt of the driving unit, and replace the worn-out one.

(2) Check the wear intensity of the rubber roller, and replace the one affecting the film advancing effect.

(3) Properly adjust the brake unit of the film-carrying roller.

(4) Check all wearing parts, and immediately replace the damaged one.

(5) Check the fastness of the wiring on the electrical terminal plate, and tighten the loosed one. Check the inverter, programmable controller and circuit board, and remove the dust or dirt on them by the compressed air.

FAQ

Q1: What type of machine for horizontal packaging do you have

Answer: We will recommend suitable models based on your product characteristics, size, and type of placement, such as model with top film loader, bottom film loader, rotary end sealing, box motion end sealing, etc. In addition, different types of in-feed conveyors can also meet different types of products feeding methods, such as chain type, belt type, feeding-on-film type, etc

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our machine for packaging is servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future.

Q3: If I buy your automatic packaging machine, what technical support can I get?

Answer: Whether buying a customized packaging machine or an automatic packaging system, we will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some custom-made automatic packing system, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packaging machine you need is ready before shipment.

Q5: How can I find the custom packaging machine I need?

Answer: We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as an packaging machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

Technical Parameters:

| Model | MP-601 |

| Center distance | 150mm |

| Bagging size range | L120-600mm Max. W250mm Max. H80mm |

| Packing speed | 35-130 bags/min. |

| Packing film width | Max. 600mm |

| Packing material | OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC etc. |

| General power | 6.8 kw |

| Power supply type | 1Ph. 220V 50Hz |

| Machine weight | 1000Kg |

| Machine dimensions | 5230 x 1380 x 1460mm |