Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

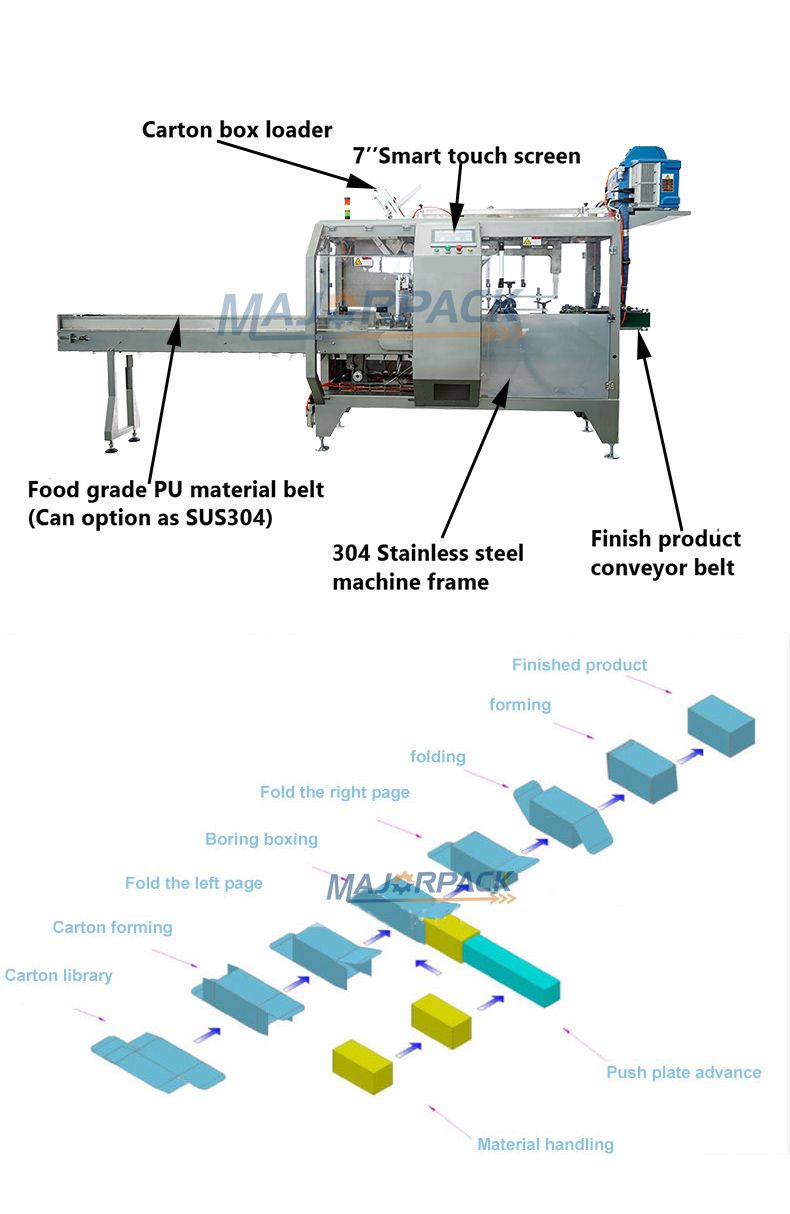

Majorpack Automatic Cartoning Machine is a fully automatic intermittent horizontal cartoner that automatically open/fold cartons, infeed products, insert leaflet into the cartons, coding and then automatically close the carton. The product range is almost unlimited and encompassing including blisters, bottle, tubes, food bar, small plastic sachet etc.

Application range:

Pharmaceutical industry: tablet, oral liquid, ampoule, vial, bagged granule, plaster, unguent, aerosol, etc.

Food industry: ice cream bar, egg roll, bread, bagged coffee, seasoning packet, milk powder, etc.

Daily chemical industry: toothpaste, soap, cosmetics, facial mask, cream, lipstick, mosquito coil incense, etc.

Hardware & electrical equipment: bearing, bulb, switch, socket, relay, charger, etc.

Automobile fittings industry: spark plug, filter, piston ring, automobile bulb, automobile electrical equipment, etc.

Plastics industry: cling film, plastic products, etc.

Entertainment industry: pen, stapler, inkpad, glue, correction liquid, poker, jigsaw puzzle, toy, artwork, etc.

Life paper: paper towel, sanitary towel, pad, cotton pad, etc.

Product advantages

| Majorpack New and Smart version machine | Others factory's machine | |

| Picture |  |

|

| Difference | New & smart version;The mechanical structure is simple, in line with the structure of artificial mechanics, reducing the labor of operators and low maintenance cost. | Old models are very common in the market, and many small manufacturers copy our appearance, but the quality after-sales is not guaranteed, confusing customers. |

| Controlled by 7servos system with fast response in 0.01 second.Each part has independent servo control, accurate positioning, stable operation and long service life of the machine. | Controlled by PLC and Frequency control,the response speed of the frequency converter is lower than that of the servo. After receiving the signal, it needs to respond for 1 ~ 3 seconds, and the positioning is inaccurate. The frequency converter can not guarantee the stability of the machine at high speed, and there are many maintenance problems. | |

|

The standard machine has the function of cover opening and shutdown, no material shutdown and automatic material replenishment, and the structure of transverse plastic door is convenient and will not harm the operator. |

The standard configuration has no protection function, and the sliding door is easy to fall and hurt the Engineer (customer feedback). |

|

|

The size of the machine is simplified and the floor area is small. 4000*1400*1980(L*W*H) |

Large floor area:4300*1850*2100(L*W*H) |

|

|

If you want to get more info,welcome to contact our enginner to get professional information. |

||

FAQ

Q1: Can tuck flap carton and glue flap carton be used on the same model of cartoner

Answer: No, it cannot. Because the tuck flap carton and glue flap carton require different mechanical motions to complete the cartooning steps, different models need to be used. In addition, the folding carton needs to be of the reverse tuck end (RTE) type.

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our horizontal cartoner is servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. We can also provide instructional videos to give you step-by-step tutorial if necessary.

Q3: If I buy your carton packing machine, what technical support can I get?

Answer: We will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some customized automatic packing line with cartoner machine, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the automatic carton packing machine you need is ready before shipment.

Q5: How can I find the suitable automatic cartoning machine I need?

Answer: We will fully communicate of the information of your tissue, including the width and diameter of the jumbo roll, pattern type, paper thickness, grammage etc.

We have nearly 30 years of experience as a machinery manufacturer and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of your tissue paper and packaging films for testing, in order to find the most suitable and cost-effective solution for you.

|

Model |

ZH200 |

ZH300 |

|

|

Packing speed (box/min ) |

50-100 |

45-80 |

|

|

Machine controller |

Seven servos |

Eight servos + 2 motors |

|

|

Box’s length(mm) |

130-200 |

150-300 |

|

|

Box’s width (mm) |

55-160 |

120-260 |

|

|

Box’s height(mm) |

35-80 |

50-100 |

|

|

Box’s requirement |

The carton shall have pre folding effect,250-350g/m2 |

||

|

Power type |

Three phase AC 380V 50HZ(Can customized) |

||

|

Power(kw) |

4.9 |

5.0 |

|

|

Total power(With glue machine)(kw) |

9.5 |

9.5 |

|

|

Machine size(mm) |

4000*1400*1980 |

4257*1605*1823 |

|

|

Air compress

|

Working pressure( Mpa) |

0.6-0.8 |

0.6-0.8 |

|

Consumptio ( L/min) |

15 |

15 |

|

|

Machine weight(kg) |

900 |

950 |

|