Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Application:

Suitable for packing fine dry powder materials, such as milk powder, spices powder, coffee powder, corn flour, laundry powder, coconut powder, fruit powder, collagen protein powder, cocoa powder, chilli powder, etc. It integrates metering, bagging, packing, sealing, date printing and counting into one.

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

FAQ

Q1: How should I choose the right VFFS packing machine?

Answer: We will recommend suitable models and configurations based on your product characteristics, size, and package type. Normally, volumetric cup filler or multi-head weigher are optional for granular, block, and flake materials; linear weigher or auger scale for powder; liquid pump for different kind of liquid. For different packaging bag types, such as pillow bags, three-side seal bags, four-side seal bags, pre-made bags, etc., we also have different models to meet your needs.

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our pouch packing machine is Servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future.

Q3: If I buy your automatic packing machine, what technical support can I get?

Answer: Whether buying a food packing machine or a grocery packing machine, we will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some big project with custom-made packing machine, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packing machine you need is ready before shipment.

Q5:How can I find the custom packing machine I need?

Answer: We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as a packing machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packing films for testing, in order to find the most suitable and cost-effective solution for you.

Q5:How can I find the custom packing machine I need?

Answer: We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as a packing machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packing films for testing, in order to find the most suitable and cost-effective solution for you.

An auger filler packing machine is a type of packaging machinery used to fill and dispense products such as powders, granules, and other free-flowing materials into containers such as jars, bottles, or bags.

The machine operates by using a rotating auger, which is a screw-like mechanism, to move the product from a hopper or storage container into the filling area.

During the packing process, the auger filler packing machine would de-aerate and homogenize the powder and break any product bridge which can form in non-free flowing powders.

Therefore, the auger is sized and configured to match the specific product being filled, and it rotates at a controlled speed to dispense the product accurately.

As the product is moved through the auger, it is measured by a sensor or a preset count. Once the desired amount of product has been measured, the auger stops and a mechanism, such as a piston or nozzle, dispenses the product into the container. The container is then moved to a sealing or capping station to complete the packaging process.

Auger filling machines are used in a variety of industries, such as food and beverage, pharmaceuticals, and cosmetics, to fill and package products accurately and efficiently. They can be configured for automatic or semi-automatic operation, and can handle a range of product sizes and shapes.

In packaging, an auger in the auger packing machine is a screw-like mechanism that is used to move and dispense free-flowing materials such as powders, granules, and other dry products. Augers are commonly used in packaging machinery such as auger filling machines, which are used to fill containers such as jars, bottles, or bags with accurate and consistent amounts of product.

The auger consists of a helical screw blade that rotates within a tube or cylinder. As the auger rotates, the blade moves the product from a hopper or storage container into the filling area. The speed and rotation of the auger can be controlled to dispense the product accurately and consistently.

Augers can be designed and configured to handle a variety of product types and sizes. For example, some augers are designed to handle powders and other fine materials, while others are better suited for granular or chunky products. The size and shape of the auger can also be customized to match the specific requirements of the packaging application.

Overall, augers are an important component of many packaging systems, providing a reliable and efficient way to move and dispense dry products into containers.

The principle of the auger packing machine is simple. When the bulk materials are fed into the hopper, the auger packing machine’s auger rotates at a constant speed and accurately dispenses and packages dry or semi-dry powdered or granular materials into containers.

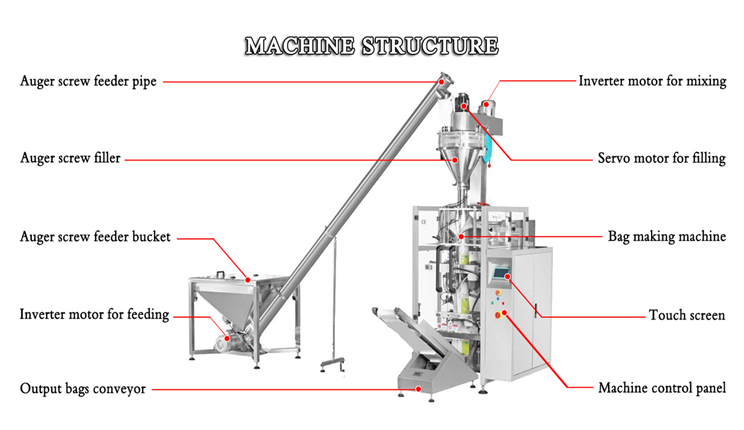

Although the auger filler packing machine has simple working process, it is construted with many components and has a complicate structure. The auger filler packing machine consists of hopper, auger screw, filling tube, drive mechanism, control panel, product compression mechanism, container conveyor, sensors, etc.

Enhance your packaging efficiency with our precision auger packing machine. Designed for accuracy and speed, this advanced system utilizes state-of-the-art auger filler technology to ensure precise measurements and consistent packaging. Streamline your production process and deliver perfectly filled packages every time with our reliable auger packing machine.

Introducing our versatile auger filler packing machine, the ideal solution for a wide range of powdered and granulated products. With customizable settings and user-friendly controls, this machine adapts to your unique packaging needs. From spices to pharmaceuticals, achieve seamless and efficient packaging with the flexibility of our auger filler technology.

Unleash the power of speed and accuracy with our high-speed auger packing machine. Engineered for rapid packaging without compromising precision, this machine is perfect for industries where efficiency is key. Increase your throughput and meet production demands effortlessly with the advanced features of our auger packing solution.

| Model | MP-420D | MP-520D | MP-620D | MP-720D |

| Bag width | 50~200mm | 50~250mm | 80~300mm | 80~350mm |

| Bag length | 50~400mm | 50~500mm | 80~550mm | 100~600mm |

| Max width of film | 420mm | 520mm | 620mm | 720mm |

| Packing speed | 15~80bags/min | 15~70bags/min | 15~60bags/min | |

| Film material | POPP//CPP;POPP//VMCPP;BOPP//PE;PET//VMPET//PE;PET//AL/PE;NY//PE;PET//PET | |||

| Air Consumpton | 0.6Mpa | 0.6MPA | 0.8Mpa | 0.8 Mpa |

| Main power | 2.5kw | 2.5kw | 2.8kw | 2.8kw |

| Power | 200V/220V/380V, 50/60Hz | |||