Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

Luocun Town, Nanhai District

Foshan, Guangdong Province, China

Send Your Mail At

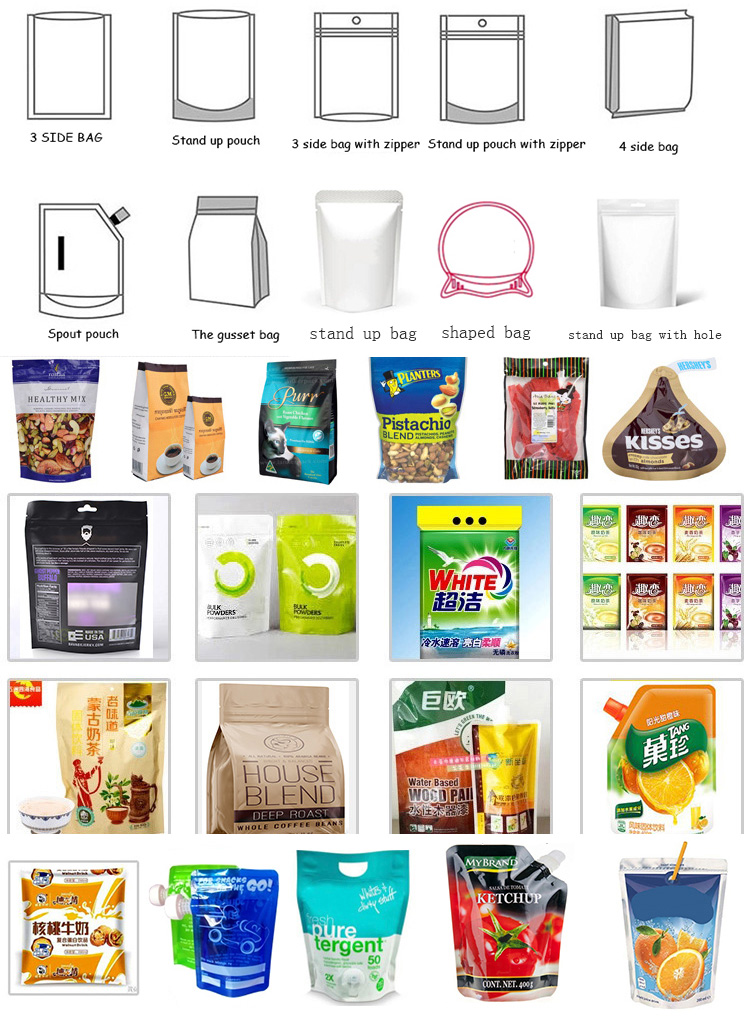

Appliaction:

Majorpack's granule single working station pre-made bag packing machine is suitable for quantitative packaging of salt, sugar, beans, food particles, rubber particles, plastic particles, fertilizer particles, feed particles, chemical particles, grain particles, building materials particles, and metal particles.

Appliaction:

Majorpack's granule single working station pre-made bag packing machine is suitable for quantitative packaging of salt, sugar, beans, food particles, rubber particles, plastic particles, fertilizer particles, feed particles, chemical particles, grain particles, building materials particles, and metal particles.

Main feature:

● Majorpack's single working station pre made bag packing machine is specially developed for the packaging application of various composite membrane preformed bags, with compact structure and reasonable action. The touch color touch screen interface is used for operation. The bag is placed on the top, and the orientation can be adjusted. A variety of bag types and sizes can be operated on a single machine. The switching is simple and requires less work.

● It is controlled by microcomputer central processor PLC, triggered by solenoid valve, driven by air cylinder, and monitored online by inductor. Soft suction cup is used to complete main effective actions such as bag taking, transferring, and opening. Emergency stop and vacuum sensing functions are set to ensure stable, smooth and safe operation.

● It can be used with various types of feeding and weighing equipment to meet the packaging requirements of different materials, such as food and non food products such as granulated materials, powder, sauce liquid, etc. The weighing equipment is touched by the host PLC, which is easy to connect. The moving mode and blanking time of the host can be adjusted according to different material properties and packaging amount to achieve the best packaging effect.

● Majorpack's single working station pre machine bag packing machine has a compact structure and can provide packing speeds ranging from 6 to 15 packages/minute to about 30 packages/minute. The cost performance ratio is reasonable. Generally, 1 to 2 workers can work to ensure its smooth operation. It is especially suitable for small and medium-sized users who have small workshop space, small packaging volume, upgrading the automation of packaging process, but do not want to invest a lot of supporting funds.

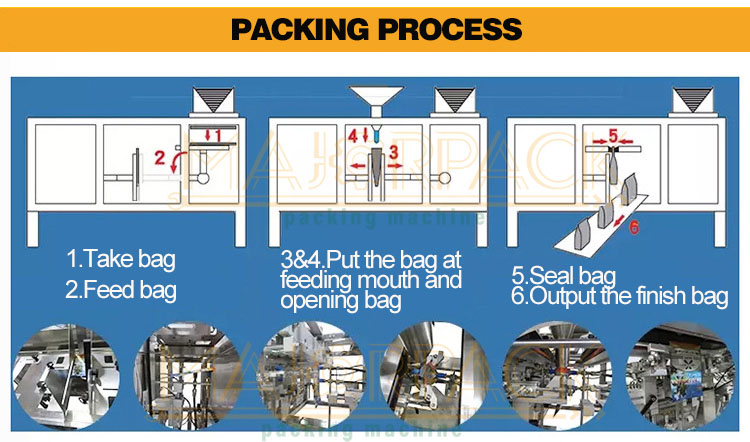

1. Automatic single working station pre-made bag packaging machine adopts an advanced PLC plus pod (touch screen) operation interface, which realizes automatic control throughout the process and is easy to operate.

2. The packaging machine controls the release of materials by the measuring machine, so as not to waste materials; The empty bag sealing prevention device controls the empty bag not to be sealed and does not waste the packaging bag.

3. The adjustment of bag width is controlled by motor. Press and hold the control button to adjust the width of each group of clamps, which is convenient and saves time.

4. Safety device: when the working air pressure is abnormal or the heating pipe fails, it will give an alarm.

5. The packaging range is wide. By selecting different meters, it can be applied to the packaging of liquid, granule, paste, powder, irregular block and other materials.

6. Equipped with liquid stirring device to prevent sedimentation of micro particle materials and liquid level control device.

Difference of pre-made bag packing machine

FAQ

Q1: How should I choose the right pre-made bag packing machine?

Answer: We will recommend suitable models and configurations based on your product characteristics, size, and package type. Normally, volumetric cup filler or multi-head weigher are optional for granular, block, and flake materials; linear weigher or auger scale for powder; liquid pump for different kind of liquid. For different packaging bag types, such as pillow bags, three-side seal bags, four-side seal bags, pre-made bags, etc., we also have different models to meet your needs.

Q2: I'm worried that I don't know how to operate your machine

Answer: Do not worry. Our pouch packing machine is Servo controlled, which greatly simplifies the difficulty of operation and commissioning. Most of the daily operation of the machine can be conducted by a few start-stop buttons and HMI. If you have different products or packages that need to be changed, we can provide instructional videos to give you step-by-step tutorial. Also, the HMI has memory function, which is convenient for you to reload the settings in the future.

Q3: If I buy your automatic packing machine, what technical support can I get?

Answer: Whether buying a food packing machine or a grocery packing machine, we will provide you with 24-hour online technical support. In addition, we can also provide you with instructional videos on the installation and daily commissioning and maintenance. For some big project with custom-made packing machine, our professional after-sales technicians can also provide on-site installation and commissioning services as per request (buyer should bear the cost for the service).

Q4: How do we build trust in the first business?

Answer: We believe that a win-win business must be based on our professional services and excellent products. Our team will fully study your needs, and clearly explain our products and solutions to you so that you can understand our services. We can take you to visit our modern factory through a video call, so that you can understand how your machine will be produced and let you know more about our products. Before delivery, we can cooperate with your partners to carry out factory acceptance test, or carry out acceptance through test video or video call. Make sure that the high quality packing machine you need is ready before shipment.

Q5:How can I find the custom packing machine I need?

Answer: We will fully communicate of the information of your products, packaging scheme, and feeding method. We have nearly 30 years of experience as a packing machine factory and can provide you with similar case videos for your reference. If necessary, we will ask you for samples of products and packing films for testing, in order to find the most suitable and cost-effective solution for you.

A multihead packing machine is a automatic packing machine equipped with multiheads which can dispense and weigh items.

A multihead packing machine, also known as a multihead weigher or multihead weigher packing machine, is a specialized piece of equipment commonly used in the packaging industry, particularly in applications where high-speed and high-precision weighing and packaging of bulk products are required.

In Majorpack, the multihead weigher packing machine has various weighing systems to meet various business requirements such as multi-head weigher, auger, electric scale, electric scale, volume cup, and so on.

Introducing our state-of-the-art Multihead Weigher Packing Machine Factory, where precision meets efficiency to revolutionize your packaging process. Our cutting-edge facility is equipped with the latest technology to manufacture high-performance multihead weighers that ensure accurate and rapid packaging for a diverse range of products.

Designed for versatility, our Multihead Weigher Packing Machines boast advanced features such as multiple weighing heads, intelligent software, and user-friendly interfaces. This allows seamless integration into various production lines, enhancing productivity and minimizing downtime.

With a focus on innovation, our Multihead Weigher Packing Machine Factory strives to exceed your expectations, providing solutions tailored to your unique packaging needs. Upgrade your production capabilities with our advanced machinery, and let efficiency and accuracy redefine your packaging process.

Are you seeking to a reliable multihead weigher packing machine factory? You can turn your eyes on Majorpack. Majorpack is one of the best multihead weigher packing machine factories in China, launching the latest packaging solutions to clients from all over the world. Majorpack has the latest robot assembly line, so Majorpack is able to provide the best multihead weigher packing machine on time.

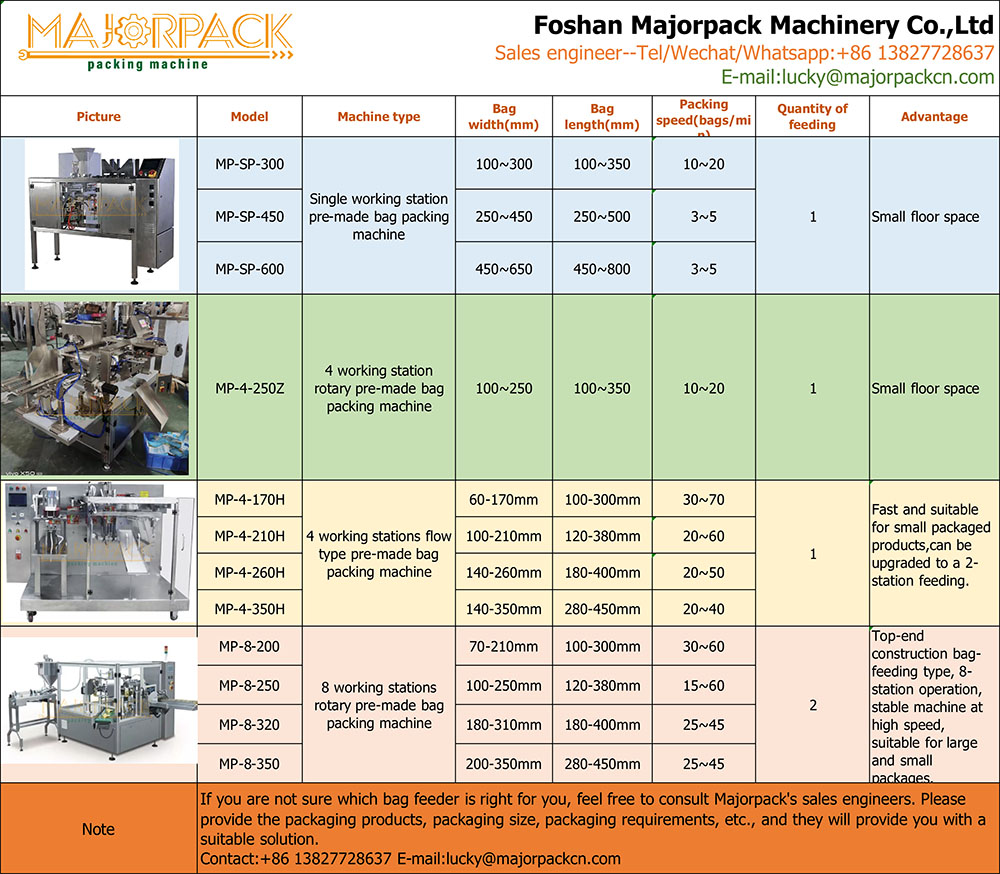

Technical Parameters of Majorpack's pre-made bag packing machine:

|

|||||||||||||||||||||||||||||||||

|

We can customize the suitable one for you according to your requiredment: 1.What product you want to pack? 2.How many grams per bag? 3.What is bag size and bag type? |

|||||||||||||||||||||||||||||||||

Difference of pre-made bag packing machine